Our engineers have performed over twenty cable-stayed bridge inspections, encompassing first generation systems through modern day designs. We have performed both non-destructive and minimally destructive evaluations, including measuring the natural damping characteristics of stays, visually inspecting strands within breached sheathing, removing end caps and protective boots to inspect strands and annular spaces, and performing chloride and pH testing of grout samples taken from damaged stays. Our engineers have utilized innovative aerial lift equipment and industrial rope access to gain proper hands-on access to complex elements.

Our key personnel have also served as engineer-of-record for analysis and rehabilitation projects. Repairs and retrofit designs consisted of addressing deficiencies associated with excessive stay-cable vibration, including exposed and corroded strands, fatigue cracks, deterioration to edge girders, and water intrusion at anchorages.

Overall, our engineers have provided engineering services for the following signature structures:

St. Croix River Crossing Bridge (2017)

I-35 Brazos River Bridges (2015 & 2017)

Margaret Hunt Hill Bridge (2013 & 2017)

Sunshine Skyway Bridge (2016)

Talmadge Memorial Bridge (2011-2018, 2020-Present)

Indian River Inlet Bridge (2013-2018)

Sidney Lanier Bridge (2011-2018, 2020-Present)

Hale Boggs Memorial Bridge (2009)

St. Croix River Crossing Bridge (2017)

Our team includes the lead team leader for the initial, element level inspection of the St. Croix River Crossing extradosed cable-stayed bridge. A baseline inspection was performed, providing the client with accurate and repeatable reporting of deficiencies. Due to geometric constraints and to minimize impact to ongoing construction activities, rope access was utilized to inspect several complex bridge elements, including the pylons and below deck stay cable anchorages. In addition to inspection, the scope of work included providing recommendations for updating the maintenance and inspection manual for the new signature structure. The 5,279-foot long bridge opened to traffic in 2017 and contains 10 main-river crossing extradosed cable-supported spans and continuous post-tensioned precast and cast-in-place box girder approach spans.

Our team includes the lead team leader for the initial, element level inspection of the St. Croix River Crossing extradosed cable-stayed bridge. A baseline inspection was performed, providing the client with accurate and repeatable reporting of deficiencies. Due to geometric constraints and to minimize impact to ongoing construction activities, rope access was utilized to inspect several complex bridge elements, including the pylons and below deck stay cable anchorages. In addition to inspection, the scope of work included providing recommendations for updating the maintenance and inspection manual for the new signature structure. The 5,279-foot long bridge opened to traffic in 2017 and contains 10 main-river crossing extradosed cable-supported spans and continuous post-tensioned precast and cast-in-place box girder approach spans.

Clients: Minnesota and Wisconsin Departments of Transportation (MnDOT & WisDOT)

I-35 Brazos River Bridges (2015 & 2017)

Our experience includes serving as team leader for the 2016 initial fracture critical and 2018 fracture critical inspections of the I-35 Frontage Road bridges crossing over the Brazos River in Waco, TX. Comprised of steel box girder-floorbeam framing systems, these parallel extradosed bridges are the first in the United States to use steel superstructure elements. To expedite the inspection and reduce impacts to the traveling public, a bucket boat was used to access the framing members.

Our experience includes serving as team leader for the 2016 initial fracture critical and 2018 fracture critical inspections of the I-35 Frontage Road bridges crossing over the Brazos River in Waco, TX. Comprised of steel box girder-floorbeam framing systems, these parallel extradosed bridges are the first in the United States to use steel superstructure elements. To expedite the inspection and reduce impacts to the traveling public, a bucket boat was used to access the framing members.

Client: Texas Department of Transportation (TxDOT)

Margaret Hunt Hill Bridge (2013 & 2017)

Our inspector experience includes serving as team leader for the 2013 and 2017 fracture critical inspections of the signature structure in downtown Dallas, TX. Access to the exterior of the fracture critical main span arch pylon required the use of rope access techniques, including the use of two inspectors descending down the 400-foot arch while connected to each other in a parallel descent. Non-destructive testing was utilized to identify any flaws within welds along the fracture-critical arch. The structure consists of a 1,197-foot cable-supported main span unit with a 400-foot tall fracture critical steel arch pylon.

Our inspector experience includes serving as team leader for the 2013 and 2017 fracture critical inspections of the signature structure in downtown Dallas, TX. Access to the exterior of the fracture critical main span arch pylon required the use of rope access techniques, including the use of two inspectors descending down the 400-foot arch while connected to each other in a parallel descent. Non-destructive testing was utilized to identify any flaws within welds along the fracture-critical arch. The structure consists of a 1,197-foot cable-supported main span unit with a 400-foot tall fracture critical steel arch pylon.

Client: Texas Department of Transportation (TxDOT)

Sunshine Skyway Bridge (2016)

Our experience includes serving as inspection team leader during the 2016 routine inspection of the signature cable-stayed bridge in Tampa, Florida. Specific elements inspected include the free length of stay-cables and upper banana pipe anchorages at the pylon interface. Access was gained utilizing a spider basket rigging system. A first generation cable-stayed bridge, the main span is 1,200 feet long with numerous concrete approach spans totaling a 21,877 foot structure length.

Our experience includes serving as inspection team leader during the 2016 routine inspection of the signature cable-stayed bridge in Tampa, Florida. Specific elements inspected include the free length of stay-cables and upper banana pipe anchorages at the pylon interface. Access was gained utilizing a spider basket rigging system. A first generation cable-stayed bridge, the main span is 1,200 feet long with numerous concrete approach spans totaling a 21,877 foot structure length.

Client: Florida Department of Transportation (FDOT).

Talmadge Memorial Bridge (2011-2018, 2020-Present)

Our engineers have served as inspection team leader, engineer-of-record, and project manager for the inspection and rehabilitation of the cable-stayed bridge. This task-order basis contract has included routine (2017), in-depth (2011 & 2020), and post-Hurricane Irma emergency (2017) inspections. The rehabilitation, completed in 2016, primarily addressed deficiencies associated with excessive vibration noted during the 2011 in-depth inspection. The structure has two 480-ft tall towers supporting the three cable-stayed main unit totaling 2040-ft. The entire structure is 7565-ft long and provides 185-ft of clearance for ocean going vessels accessing the Port of Savannah. The bridge was accessed using snoopers and rigging.The Talmadge Memorial Bridge consists of prestressed, post-tensioned continuous approach spans and a cable-stayed main span, traversing a total length of approximately 7,570 feet.

Our engineers have served as inspection team leader, engineer-of-record, and project manager for the inspection and rehabilitation of the cable-stayed bridge. This task-order basis contract has included routine (2017), in-depth (2011 & 2020), and post-Hurricane Irma emergency (2017) inspections. The rehabilitation, completed in 2016, primarily addressed deficiencies associated with excessive vibration noted during the 2011 in-depth inspection. The structure has two 480-ft tall towers supporting the three cable-stayed main unit totaling 2040-ft. The entire structure is 7565-ft long and provides 185-ft of clearance for ocean going vessels accessing the Port of Savannah. The bridge was accessed using snoopers and rigging.The Talmadge Memorial Bridge consists of prestressed, post-tensioned continuous approach spans and a cable-stayed main span, traversing a total length of approximately 7,570 feet.

Client: Georgia Department of Transportation (GDOT)

Indian River Inlet Bridge (2013-2018)

Our experience includes serving as lead team leader for the initial (2013), routine (2016 and 2018), in-depth (2014), and special (2015 and 2017) inspections of the cable-stayed spans of the bridge. Rope access was used to inspect the full length of each cable stay as well as pylon exteriors. In-depth access of complex components included removal of anchor caps to inspect the annular space. The Charles W. Cullen Bridge carries four lanes of Delaware Route 1 as well as bicyclist and pedestrian traffic over the Indian River Inlet. The bridge consists of four 250-foot pylons and 152 stay cables supporting the deck. The structure is 2,600 feet long with a main span of 950 feet and was opened to traffic in January 2012 with a price tag of $150 million.

Our experience includes serving as lead team leader for the initial (2013), routine (2016 and 2018), in-depth (2014), and special (2015 and 2017) inspections of the cable-stayed spans of the bridge. Rope access was used to inspect the full length of each cable stay as well as pylon exteriors. In-depth access of complex components included removal of anchor caps to inspect the annular space. The Charles W. Cullen Bridge carries four lanes of Delaware Route 1 as well as bicyclist and pedestrian traffic over the Indian River Inlet. The bridge consists of four 250-foot pylons and 152 stay cables supporting the deck. The structure is 2,600 feet long with a main span of 950 feet and was opened to traffic in January 2012 with a price tag of $150 million.

Client: Delaware Department of Transportation (DelDOT)

Sidney Lanier Bridge (2011-2018, 2020-Present)

Our engineers have served as inspection team leader, engineer-of-record, and project manager for the inspection and rehabilitation of the Sidney Lanier Bridge. This task-order basis contract has included multiple routine and special inspections (2011, 2015 & 2016) and multiple rehabilitation projects to primarily address deficiencies associated with cable vibration, including repairs to cable-stays with exposed strands and installation of external dampers at all 176 stays. The structure consists of a two-pylon cable-stayed structure supporting a main river span and two back spans (total length of 2,500 feet) with a post-tensioned concrete deck supported by concrete edge girders and post-tensioned concrete floorbeams. Thirty-four approach spans consist of ten prestressed or post-tensioned concrete beams for a total bridge length of 7,780 feet.

Our engineers have served as inspection team leader, engineer-of-record, and project manager for the inspection and rehabilitation of the Sidney Lanier Bridge. This task-order basis contract has included multiple routine and special inspections (2011, 2015 & 2016) and multiple rehabilitation projects to primarily address deficiencies associated with cable vibration, including repairs to cable-stays with exposed strands and installation of external dampers at all 176 stays. The structure consists of a two-pylon cable-stayed structure supporting a main river span and two back spans (total length of 2,500 feet) with a post-tensioned concrete deck supported by concrete edge girders and post-tensioned concrete floorbeams. Thirty-four approach spans consist of ten prestressed or post-tensioned concrete beams for a total bridge length of 7,780 feet.

Client: Georgia Department of Transportation (GDOT)

Hale Boggs Memorial Bridge (2009)

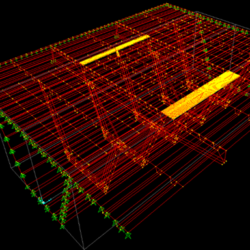

Our experience includes providing bridge engineering services to rehabilitate and perform a fatigue life evaluation of problematic cracking at the interface of steel tub girders and the orthotropic deck of this 11,248-foot-long structure’s cable-stayed spans. A three-dimensional structural analysis of a steel box girder segment was created to determine the remaining fatigue life and to recommend repair methods to arrest noted cracking at the welded connections of transverse stiffeners to the orthotropic deck. The bridge was constructed in 1983 and consists of twin steel trapezoidal box girders with a steel orthotropic deck. The bridge carries four lanes of I-310 over the Mississippi River.

Our experience includes providing bridge engineering services to rehabilitate and perform a fatigue life evaluation of problematic cracking at the interface of steel tub girders and the orthotropic deck of this 11,248-foot-long structure’s cable-stayed spans. A three-dimensional structural analysis of a steel box girder segment was created to determine the remaining fatigue life and to recommend repair methods to arrest noted cracking at the welded connections of transverse stiffeners to the orthotropic deck. The bridge was constructed in 1983 and consists of twin steel trapezoidal box girders with a steel orthotropic deck. The bridge carries four lanes of I-310 over the Mississippi River.

Client: Louisiana Department of Transportation and Development